June 13, 2018 8 Comments

Hi, Filastruder here. We want to talk to you about filament.

Before we get started, you should know this is a long post. If you’re here and curious about the quality filament we’re now carrying and Masterspool, but aren’t really interested in the details, here’s a quick summary:

We're calling it Veracity. Why?

Veracity (ve·rac·i·ty)

1.) habitual observance of truth in speech or statement; truthfulness:

2.) accuracy: to question the veracity of his account.

3.) correctness or accuracy, as of the senses or of a scientific instrument.

In short, we have named this filament Veracity as we have taken a very open approach - from disclosing the specific resin used to sharing the exact production line data on a per spool basis - we're valuing truth, openness, and accuracy.

Now, for those who want to dive deep into the details, read on.

The Filastruder was born out of a desire to make low-cost filament at home, allowing users to save money, and experiment with various plastics and colors. Until now, we haven’t really carried filament, choosing to stay out of the hyper-competitive filament market and focus on providing other products.

We didn’t want to become just another filament reseller as there are plenty of those as it is, but we did learn a lot a LOT about what makes filament great or not along the way. Then, RichRap came along and as he so often has before, changed the game with an innovative idea, the Masterspool. We wanted to help push that revolutionary idea forward, meaning it was time to start carrying filament in earnest.

Introducing Veracity Filament:

Better for your printer.

Better for the environment.

We’ve worked with Keene Village Plastics (KVP) to carry four materials (ABS, PLA, Pro-PLA, PETG). These materials are available in both conventionally spooled and refill Koil varieties. Some more details that apply to all Veracity materials we sell:

Better for your printer:

Filament diameter data available on a per-spool basis, when purchased from Filastruder.

This is something we’re really excited about. Every individual product that comes off the production line will have a unique barcode that allows us to track everything about that particular reel or Koil. The data is stored for 5 years, so if anything comes up during this time with any client we can research that specific item. The serial number associated with each barcode links your spool of filament to a database of filament diameter measurements that were captured during manufacturing.

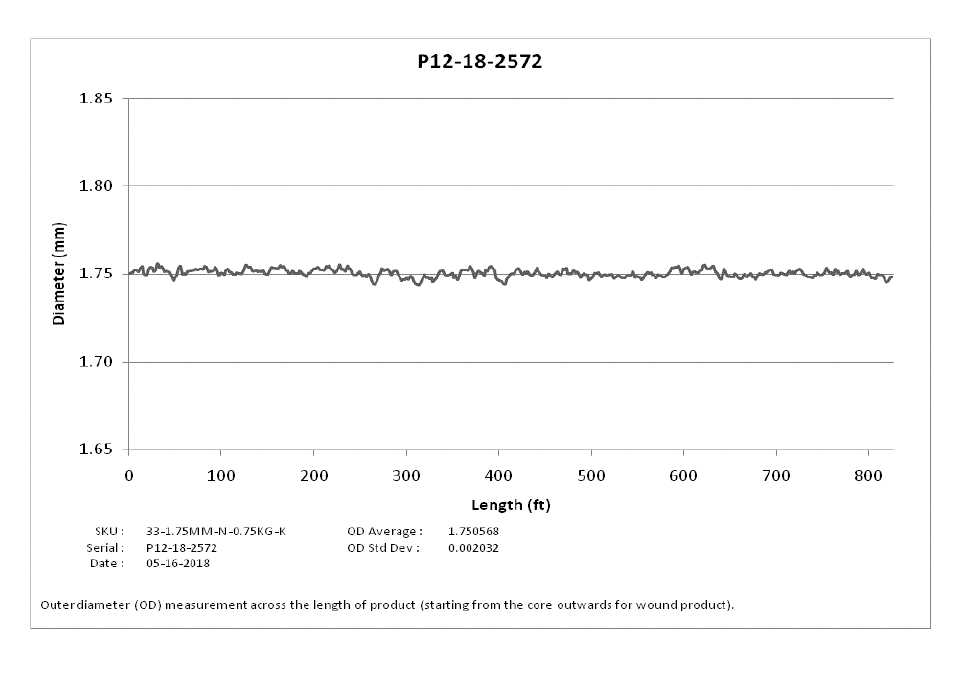

Keeping with the theme of knowing exactly what you’re getting, this means you can look up the triple-axis filament diameter data for your specific spool of filament. You’ll be able to see standard deviation, minimum diameter, maximum diameter, production date, and more. The photo to the right shows the triple axis measuring system, called a laser micrometer.

This measurement data, comprised of 300 laser scans per second, is directly dumped into a graph for that specific spool, an example is done below. There’s no averaging or filtering - all the data is right there in the plot.

Example of a typical filament diameter measurement graph - this is actual data from a spool in our first shipment.

KVP’s processes are unique in the industry. Here’s a few examples:

Made in the USA by Keene Village Plastics, a company with more than a decade of experience producing filament. Knowing you can trust who makes your filament is important. That’s why we’re not white labeling this filament. KVP is the original supplier to many companies including Makerbot, 3D Systems, and Lulzbot.

KVP helped establish the quality standards that those OEMs use today. All of KVP’s production lines (15 in a 30,000sqft new facility, 500,000KG annually) are tied to a central production and quality control system. The quality database stores information that includes: production date, technician, line number, settings, material and blends and colors, and up to 250,000 measurements of the filament.

A few of the extrusion lines at Keene Village Plastics, located in Barberton, OH.

Made from 100% virgin polymers, no regrind. We’re rolling out four materials, and there’s no secrets here either. We make public the raw resin for each material, so you know exactly what you’re getting. No marketing hoopla, just real good filament. MSDS and datasheets available for each material.

Here’s the specifics:

Melt filtered at 20-80 microns to ensure there are no contaminants in your filament. Melt filtration is an essential part of filament production. Just before the filament leaves the extruder on the production line, it is forced through a set of very fine screens called a screen pack.

These screens remove and dust, dirt, and debris that may have found their way into the polymer throughout the supply chain. Using very fine melt filtration comes at a cost - reduced production speed, but we think it’s worth it to get material that is free contaminants - even contaminants that could jam smaller 0.15mm nozzles.

Better for the environment.

Hopefully by now we’ve made a pretty strong case for the quality of this filament.

For those of you who aren’t quite ready to make the leap to Masterspool, we have good news. We will be selling KVP filament on conventional spools and you can feel free to stop reading now. But, if you’re tired of empty spools piling up and are looking to save money, read onward!

The Masterspool is a refillable filament solution. Instead of buying filament on a spool, it comes in a vacuum-packed bag, which is then mounted onto a reusable spool. You read that correctly -- a reusable spool.

Example of placing a refill coil on the Masterspool

We found Keene Village Plastics and worked with them to produce Veracity, and reached out to RichRap to thank him for his contribution. Here are some of the details of using the refill system:

Masterspool’s shipped weight is 30% lighter than a conventional spool of filament. By removing the spool, shipping costs are reduced, and accordingly, the carbon footprint is reduced as the spool’s plastic is not needed plus there’s less fossil fuels burned to get the shipment to you. And that’s a win for everyone involved.

No more throwing empty spools in the trash. We’ve all been there. First, it starts with putting Christmas lights on the empty spools, then extension cords. You might even print out an organizer. But eventually, they’ll end up being discarded. No more!

$2 of every filament refill (“koil”) goes directly to RichRap. Filastruder is a believer in supporting the community that helped get 3D printing to where it is today. In fact, Giving Back is one of our company’s three initiatives -- Going Green, Giving Back and Education.

This innovation is exciting for us. Finally, there was a better solution out there than the status quo. And we wanted to see how we could push that forward for the community, especially since we take so much pride in reusing and recycling everything we can. Read more about our Going Green initiative.

These initiatives are why we support CNC Kitchen and Toms3DP on Patreon, and why we're proud to announce $2 from every filament koil sold will go directly to RichRap in appreciation of his efforts with Masterspool. If you aren't already subscribed to him on YouTube, check him out!

So to summarize, we are really excited about Veracity filament. Doing so aligns with our company’s initiatives, and we believe it’s worth you trying. In addition to the filament being better for your printer and the environment, you will be able to view the filament diameter data on a per-spool basis, when you purchase it from Filastruder.

Additionally, the Masterspool is a game changer that will allow the use of filament refills. It will save you on shipping costs and keep you from stockpiling empty spools.

Now the fun part, go check out the Veracity collection and please share your prints with us on social media.

Happy printing!

June 22, 2018

These coils are not the same setup as RichRap’s spec. You’re using 4 tie wraps and have a coil width of 55mm versus his 3 tie wraps and 46.7mm width. Are these your final dimensions? I can work with any of them, but I’m looking to design/print/build a truly universal master spool. If these are what you’re sticking with, I’ll design accordingly.

Thanks!

June 15, 2018

@Drew, @Martin, nice catch, typo corrected, thanks!

June 14, 2018

I’m with Mark Hammond. I see you have an Amazon purchase option, but the $10 shipping fee (for me) makes the cost per roll go above the filament available on Amazon with free 2 day shipping. Hatchbox and eSUN to be specific. I realize buying in bulk is an option to get rid of the fee, but it would be nice to not have to do that.

June 14, 2018

If it were available on Amazon you would have my support as well as 99% of consumers.

June 13, 2018

Drew’s right. From the graph, it looks likely that the .0045 mm figure is the correct one - which is a bit less than two ten-thousandths of an inch. You need to stop being so modest. :)

June 13, 2018

Is there any way to make shipping cheaper? Your 750g PETG refill is US$20 which is great, however shipping to Australia is US$30, so the total order is US$50. Das Filament are able to send their 850g MasterSpool refils anywhere in the world for €9.5 with tracking.

June 13, 2018

For what it’s worth .002" is .0508mm. Looks like you’re an order of magnitude off.

Comments will be approved before showing up.

TIM ELMORE - FILASTRUDER

August 08, 2018

Hi Brian, sorry for the late reply, we didn’t get notified for some reason.

RichRap’s spool was designed for 750g refills, but we wanted to offer 1kg refills as well. As a result, the refills are wider, but they do work just fine with RichRap’s spool – you just don’t screw the two halves together quite as much.

As for the zip ties, using 4 results in more secure packaging, but you’re welcome to cut one off on arrival to make 3 zip ties. :)