May 29, 2018 4 Comments

Since day one of Filastruder, we have prided ourselves on being a company that is committed to limiting waste and giving back to the world. From this vision, we created three initiatives: Going Green, Giving Back, and Education. We have mentioned these initiatives before in newsletters, but we wanted to dive a little deeper to let you know how we are doing with each one. What follows will be a series of blogs -- one per initiative. Today, we are discussing Going Green.

Going Green

Packing and Shipping

Our vision is to have as close to zero waste as possible in everything we do. We have taken several tangible steps to achieve this goal.

One of the first things we decided to do was reuse as much of our inbound packaging as we could, and we are excited to report 100% of all void fill packaging that leaves our facility is reused. Whether it’s styrofoam peanuts, air pouches or packing paper, we use all incoming void fill. We are also now able to reuse all the cardboard boxes we receive as well. About half of those are recycled and occasionally reused, but any box that can’t be used for shipping or storage is shredded and turned into void fill.

What all that means is we are able to ensure about 80% of our outbound packaging is comprised of reused materials. Just about the only thing that is not reused or recycled at Filastruder is packing tape and shipping labels. We’re still trying to figure out how to accomplish that one. We’ll keep you posted if we ever figure it out.

Here are some pictures of our packing materials:

Renewable Energy

We are also excited to announce we are officially 100% solar powered, using grid-tie roof mounted solar panel arrays. Going solar was something we talked about for awhile. It was one of the biggest ways we knew we could back up our talk of going green. It took more planning, research and patience than simply not wasting inbound materials. Truth be told, some of us weren’t sure we would really be able to make it happen, but once the panels went up and we started seeing them in action, we were all really excited to be solar powered.

For those interested in our set up, here’s what we’ve called the “nerd data:”

Below is a picture of some of the panels themselves:

|

|

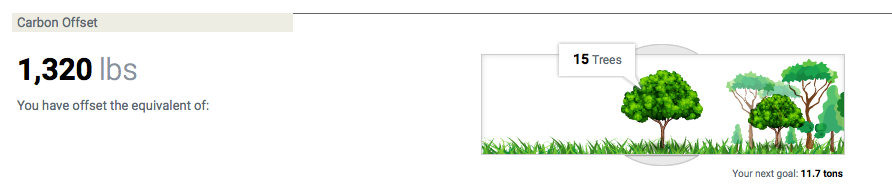

Additionally, here is a look at our current carbon offset from the panels:

But we’re not done. We are constantly looking for new ways to continue going green. We are currently thinking through plastic recycling and carbon offsets for shipping. We’ll keep you posted on those. If you happen to have any thoughts on how we can do that, or any other ideas on how we can keep going green, feel free to slide into our DMs and let us know. Or, if you prefer, feel free to email your ideas to us at marketing@filastruder.com. We’d love to hear from you!

September 22, 2018

I think both of you pretty much summed up the current problem at hand. The grinder is the first step in getting this idea of small scale recycling into homes, but the business side of it has these hurdles that will need to be overcome somehow to achieve that on a larger scale and at a lower price. That being said, I really want a grinder for in home use for this, maybe even one cheap enough to give to friends and family, so I think you should still make it. :)

September 05, 2018

Hi Eric. Thanks for the question, and it’s a good one. The problem is twofold – liability and cost (both money and time). A grinder, regardless of whether hand powered or motor powered, will be expensive as the hardened steel blades are not cheap, especially in the relatively low volumes we’d be getting them manufactuered in. The other problem is liaiblity. Making the grinder hand powered reduces, but does not eliminate this. But then the time spent cranking is added to the effective cost, making it more expensive to “use.”

Recommended options are a used granulator from eBay, or a FilaMaker.

August 30, 2018

Any thought to maybe a hand grinder to help people recycle failed prints/supports/brims/rafts/etc? Filastruder made extrusion cheap enough a home user can afford it even if they don’t plan to use it for business purposes, if something similar could be done for grinding up plastic that would be great even if you can only mix in 10-20% recycled with new.

Comments will be approved before showing up.

Dennis B Bilik

September 23, 2018

Oh, and for the label problem noted above in Part 1, small laser etcher to set on the box and have it etch the label onto the box. Packing tape probably doesn’t have as cool of a solution. If it doesn’t work it would still be cool to try out.